Chosing the right jewelers saw blade size is VERY important. If someone had told me that at a jewellery making course, it would have saved me a lot of frustration. But I guess that a short course provides very little time to teach such basics as chosing the right jewelers saw blade size. Imagine, you’ve got 3-4 hours and a bunch of students eager to start (and finish) their project. Would you bother them with all these numbers which they probably would never need. You just give them the most popular saw size 3/0 which you have ordered in wholesale quantity. And if they break it they would most probably blame it on their own lack of skill. Just replace it. OK, the material damage is limited as saws are not expensive. But what about the moral damage to the (aspirant) jewellery maker?

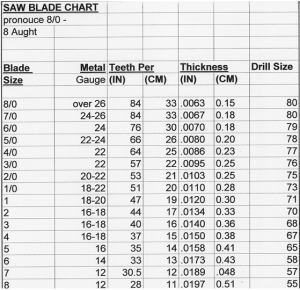

The online supply shops, at least the one where I buy my supplies, are not much helpful either. All they state in their product description is the size like 7/0 or 1/0. And you have to guess the rest. This table is really very helpful in defining the right jewelers saw blade size.

But what this table DOES NOT tell you is which size blade to use for which work. The rule of a thumb is that the thickness of the saw shall correspond to the thickness of the material being pierced or sawn. So if you pierce an intricate pattern in a 0,5 mm (gauge 22-24) silver plate you’d probably need size 5/0. For thicker plates go up until 1. But if you want to saw off a large chunk of silver (or gold) – which always remains after casting with the Delft casting method – use #1 and not less, maybe even more.

Not only the thickness but also the hardness is important. Silver is a soft metal, so the jewelers saw blade size can be one degree less than for harder metals such as gold or steel.

And last but not least. The teeth density (teeth per cm) is also important. More teeth means higher sawing speed and precision. But also higher chance to get stuck, especially going around the corners. The universal advice is – go as smoothly as you can, don’t stop moving and keep the saw blade perpendicular to the surface. And of course, the blade has to be literally high-strung in the fretsaw. But this is the basic knowledge they always teach you at a course.

Leave a Reply